This is Part 2 of a two-part series that addresses nuclear power plant safety objectives and the associated safety measures designed to achieve those objectives. The previous article explained that plant safety objectives are accomplished by means of a three-level defense-in-depth approach. The Level 1 (prevention) measures, primarily associated with assuring normal plant operational safety, were addressed in the previous article.

Operational Upset/Accident Safety

In addition to normal operational safety objectives, nuclear power plants have similar safety objectives for operational upset conditions and potential accident events. Plant safety for these situations is accomplished by means of defense-in-depth Level 2 (protection) and Level 3 (mitigation) measures that

1) maintain reactor core reactivity control,

2) provide reactor coolant inventory control,

3) provide reactor core heat removal capability,

4) provide reactor containment building heat removal capability, and

5) assure radioactivity containment.

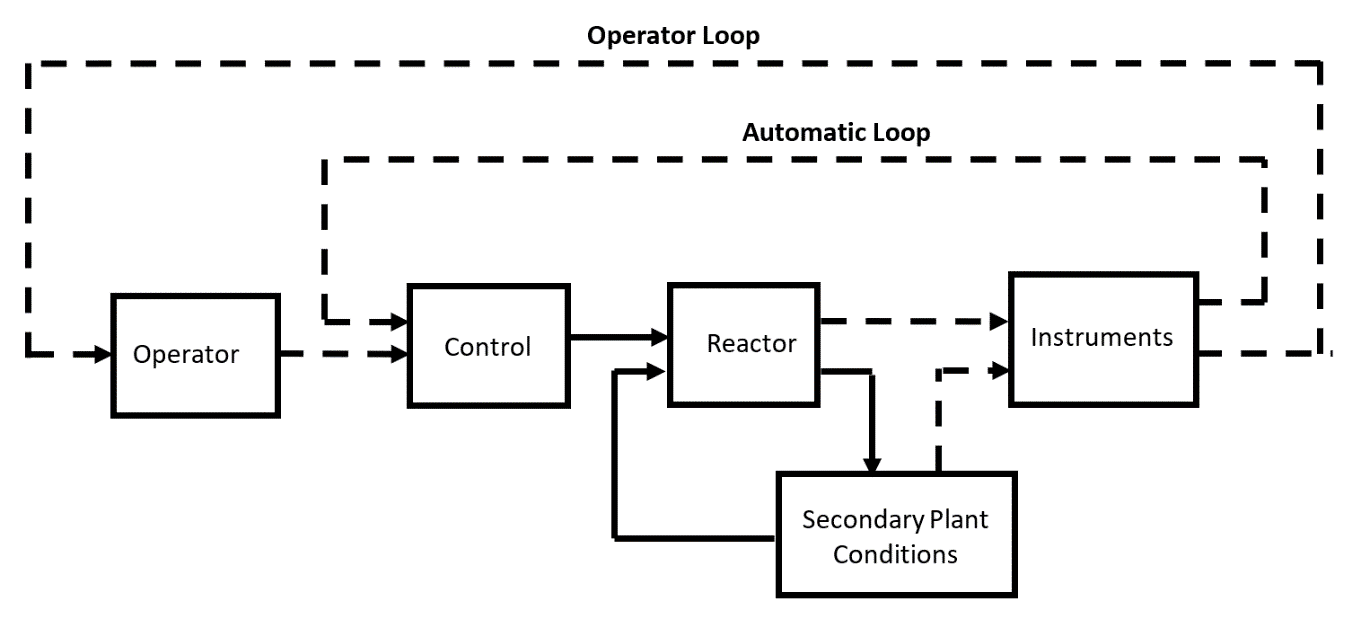

For normal plant operations, reactor operators are afforded Level 1 reactor control capabilities based on information provided by plant monitoring instrumentation via an operator information loop. For circumstances where operator manual actions may be inadequate, appropriate Level 2 actions are automatically initiated via an automatic information and control loop. This reactor instrumentation and control system is illustrated by the graphic below.

Reactor Core Reactivity Control

The redundant Reactor Protection System (RPS) ensures the reactor core fission chain reaction is terminated for all off-normal operating conditions and events by rapid automatic insertion of control rods into the reactor core. Numerous off-normal plant conditions provide inputs to automatically actuate the RPS.

Reactor Coolant Inventory Control and Core Heat Removal

Emergency Core Cooling Systems (ECCS) are redundant and independent safety systems that provide reactor coolant system makeup water and reactor heat removal in the event of a loss-of-coolant accident. Both high-pressure and low-pressure injection systems are available to provide makeup water to the reactor coolant system as the system pressure decreases. Low-pressure injection pumps ultimately recirculate water accumulated from a loss-of-coolant event and heat is removed from the recirculated water via the plant’s decay heat removal system heat exchangers.

Reactor Containment Structure Heat Removal

The Post-Accident Heat Removal System removes heat from the reactor containment structure to prevent over-pressurization following a loss-of-coolant accident, thereby assuring containment structure integrity. Pumps recirculate accumulated water to containment spray headers and heat is removed from the recirculated water via the plant’s decay heat removal system heat exchangers.

Radioactivity Containment

Gaseous and liquid radioactive waste processing systems ensure that all gaseous and liquid effluents from the reactor containment structure are treated to remove radioactive material prior to release so that all post-accident discharges are below regulatory limits.

Engineered Safety System Reliability

The reliability of nuclear power plant engineered safety features is assured by incorporating the principles of redundancy, diversity, and physical separation into their design. Emergency safety systems, including emergency electrical power systems, are completely redundant. Diversity of emergency equipment precludes loss of emergency functions due to common-mode component and system failures. Physical separation of redundant safety systems and equipment, including control and instrumentation electrical cables, assures protection from localized events such as fire and flooding.

The fail-safe principle is also incorporated into the design of plant components. This principle assures that when critical components fail. They fail in a safe condition so they don’t complicate an operational upset condition.

Generation 2 vs. Generation 3+ Safety System Designs

There is a fundamental safety system design difference between currently operating Generation 2 nuclear power plants and the new Generation 3+ power plants. Generation 2 plants depend on active safety measures; for example, AC and DC electrical power for equipment, and early operator intervention for operational upset events. Generation 3+ plants are designed with passive safety measures — for example, making use of gravity, natural circulation cooling, and high temperature-resistant materials — and require no operator intervention to manage or terminate operational upsets.

Related Articles

Basic Nuclear Reactor Safety — Part 1

Dispelling Irrational Fear of Radiation

Understanding Radiation Risks & Benefits

The Dynamic World of Radioactive Decay

Latest Low-Dose Radiation Research Program a Retread?

Radiation Dose and Cancer Risk